SEWING MACHINES

Rudolf’s obsession with vintage sewing machines started over twenty years ago, when he found an antique hand cranked model in a local second-hand store. As it turned out, its most essential part, the bobbin case, was missing. To this day no replacement has been found; it still does not work.

Over the years, a collection of some 35 machines from as far back as 1903 has been assembled. Many of these pieces are in working order and some are used on a regular basis. As well as their aesthetic qualities, these machines are interesting for their mechanical designs, styling and history.

There is no beauty without decay. A.

By means of observation and the study of how these marvels of engineering actually function, Rudolf has taught himself to restore apparent wrecks to working condition. His approach to restoration is to repair only as much as is required for safe, reliable operation and to merely polish up the rest. This highlights the beautiful patina in the original painted and metallic surfaces.

Parts that are missing are replaced with similar original spares or made up in a manner sympathetic to the machine. Major cosmetic treatments such as re-painting are absolutely out of the question, as such actions would ruin not only the original fabric, but also erase the item’s history.

Should you be interested in owning such a machine, Rudolf can supply fully restored machines to suit your requirements. You might even find your nan’s old machine tucked away and forgotten about somewhere. From a simple clean, oil and tune up to a full restoration, Rudolf can service and repair your vintage sewing machine; and show you how to look after it. Please contact Rudolf to arrange an inspection and assessment of your machine.

The Collection

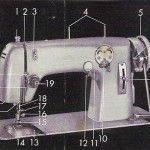

In the list that follows, the machines in Rudolf’s collection are described in detail and some of them have instruction manuals available for you to download. The links to the .pdf files are shown in red and will open in a new tab/window. To view larger format pictures, just click on the thumbnails. Please note that this section is a work in progress and new entries will be added or updated from time to time.

Anker RZ

Anker Werke AG was one of several sewing machine manufacturers based at Bielefeld in Germany and their products were of exceptional quality. Strange is the fact that the designator ‘RZ’ was used for at least two seemingly unrelated models. Rudolf owns two very similar machines, a black one with Serial number 1591555 I and a green version Serial number 1682408 P. The former still has its original warranty certificate dated 17 January 1953. It was sold new at “Amsterdamsche Naaimachinehandel Lewenstein’ in Holland, which explains why the instructions booklet is in Dutch.

The only difference, apart from the colour, is that on the earlier machine, the needle position can be shifted from centre to right only, whereas in the later model it shifts to the left as well. This feature, together with the presser foot as a guide, makes for perfectly positioned seams.

Instructions (Dutch):

Anker RZ Automatic

Bernina 117K

Model 117 K, made in Switzerland , was Bernina’s first zigzag sewing machine. Its cast iron construction makes it very sturdy and capable of sewing many layers of denim. It features a knee lever for lifting the presser foot and is housed in its original timber cabinet. This particular example dates from 1939 and came furnished with a set of twin needle clamps and matching pin-tucking feet, which would have been sold as an optional accessory. As is the case with many early domestic machines, the 117K were designed for System 287WH round-shank needles. These are not self-centering, so care must be taken to insert them correctly.

Bernina 117L

Improved version of 117K, also in a cabinet.

Bernina 125

This compact little machine dates from 1953. Its body is made of die cast aluminium, and the built-in electric motor is operated by means of a knee lever. Its austere post WWII design is simplicity itself; every single part of it serves a purpose and is utterly functional. It is a free-arm machine, with a separate extension table. The bobbin case is of the same design as the larger ‘Record’ models.

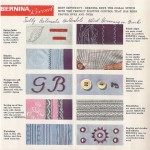

Bernina 530-2 Record

Arguably the best domestic sewing machines money could buy in 1960, the Bernina Record features many innovations, including thirteen built-in stitch patterns. An original sales brochure and a quirky promotional sticker were among the bits and pieces that came with this machine. There is a hand written note quoting the all inclusive price of £119- 10-0 – a substantial sum, equivalent in those days to six or seven weeks’ wages! Beautiful Swiss engineering on the outside as well as on the inside.

Instructions (English):

Bernina 540 Favorit

Predecessor to 640-2, flat bed version of Bernina 540 Record.

Bernina 640-2 Favorit

The Favorit models were the flat bed equivalents of the Record machines. Identical parts were used from the base plate up in both versions. Below the base plate was a different story altogether. While the Record machines already had the bobbin case still used today, the Favorit employed the same set-up as the 117K. The Favorit was available as a portable machine in a wooden box, or mounted in a table. These machines were often used in industrial settings, where they would have had a heavy duty clutch motor located beneath the table.

Serial number: 63089144

Instructions (English):

Bernina 717 Minimatic

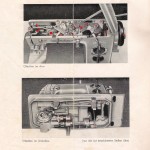

Bernina Minimatic machines were produced in three versions, namely the 707 free arm, 717 flat bed in box and 727 flat bed in die-cast base. All three were identical from the bed plate up, only the bases were different; shown here is a 717 model. This particular machine was made in 1969, and it bears the ’75 years of Gegauf’ anniversary badge. Compact yet versatile, these little gems feature a number of useful stitch patterns. Produced in the late 1960s and early ’70s, the quality of these machines is on par with other Bernina products of the period. In actual fact, they share many parts with the contemporary Record and Favorit models. Even the styling and colour scheme matched that of the big sisters. A look behind the scenes reveals quality engineered parts, which after more than forty years still appear as new!

Instructions (English):

Bernina 730 Record

This model is affectionately referred to as ‘Panzer’. In deed, it is built like a tank, it just looks a lot better! The last in the line before the angular 800-series displaced the curvy, aesthetically pleasing yet functional design. Distinguishing features of this model include twenty fancy stitch patterns, semi-automatic buttonhole and the bobbin winder under cover at the top right. As with the Minimatic models, the thread tension is built into the lid and the machine can be threaded up with one hand. The machine shown here was made in 1969.

Instructions (English, early edition):

Elna Supermatic

Elna ‘Supermatic’ is a true marvel of engineering for its time. A mechanism accepts exchangeable ‘Elna Discs’ to produce complex stitch patterns. As the edges of the rotating disc are traced, the lateral needle position as well as the longitudinal movement of the feed dog are influenced. The free-arm design allows for stitching even in tight spaces such as sleeves and trouser legs.

These machines were made with either knee-lever or conventional foot control actuators. Presser feet, cams, bobbins and thread reels were housed in a removable plastic accessory box, and the machine’s metal case could be converted into a sewing surface, essentially turning the machine into a flat bed design.

Elna SP/ST/SU

Elna SP/ST/SU machines were a modernised ‘Supermatic’. The only real difference is the outer appearance. Internally, most components and the ‘Elna Discs’ are the same.

Instructions (English):

Favta Darling

Helvetia Portable Model 40-4

This delightful machine bears the name of the country it was made in, namely Switzerland. An excerpt from a book states that the Swiss Sewing Machine Works in Lucerne started operating in 1895. The brand name ‘Helvetia’ on their machines also became the company name from 1912. It once belonged to a certain Mrs Ethel Lockwood, who apparently bought it new. She eternalised her name on top of the accessory tin. Everything fits neatly into the very cleverly designed storage box; the light is incorporated into the oh-so-50’s streamlined machine head. The ‘Portable’ is a straight stitcher, made versatile by a variety of presser feet. As well as the buttery yellow shown here, the machines were available in deep red and moss green. The instruction booklet, in English, was printed in July 1953; there was an edition of 5000 units.

Instructions (English):

H.G.Palmer ‘Princess’

Included here by popular demand is the manual for the H.G. Palmer ‘Princess’ sewing machine. Similar to the Lemair-Helvetia below, these machines were made in Japan and equipped with electrical components after import to Australia.

Instructions (English):

Lemair-Helvetia Model 454

Not much information is available about the Lemair brand, except that it was introduced to Australia in 1956. Today, they are known air-conditioning units. What the connection with Helvetia is, is a mystery. According to the instruction manual, the machine head was made by Brother of Japan. Badged with the Lemair brand and equipped with locally produced electrical components, they were ready for the Australian market. The original guarantee card for machine head serial no. 128641 and motor serial no. 15073 was issued on 26 January 1962. Inspiration for the styling was no doubt taken from contemporary automobile design.

Instructions (English):

Necchi BU Mira

This machine is Rudolf’s workhorse; while its rating plate says it’s a Mira model, the instruction booklet is for a Nova. It appears, judging by the prices, that the Mira was the top of the line in its day. Made in Italy in 1955, it was sold in a sewing machine shop in Istanbul, Turkey. When Rudolf discovered this machine in a Sydney junk shop, it still had its original European plug.

While being a basic zigzag machine, it is well designed and has all the features a sewing machine needs; adjustable stitch length, stitch width and needle position. Fitted with an electric motor and light, a treadle is provided inside the cabinet for emergency back-up. Just as well Rudolf knows his way around a sewing machine, because instructions are in Turkish! The word ‘kolu’ appears to translate into ‘lever’ in English.

Necchi Lydia 3

There is one of these machines in the collection at the Museum of Modern Art in New York as an example of outstanding industrial design. While it may look fabulous, it turned out to be not very practical for sewing! One major drawback about the design was, that the needle position is set and cannot be altered; this despite the array of fancy stitch patterns that are built in. As well as that, the machine runs quite noisily and the quality, while appropriate for the 1970s, is not nearly as good as it was in earlier machines.

Pfaff 30-31

Made in Germany in 1950, this machine is a fine example of precision engineering. Macro photography reveals incredible detail and some interesting angles. Powered by an English ‘Sew-tric’ motor with built-in light, it required complete re-wiring. Lovely new cloth covered cord has taken the place of an ugly plastic cable; it is fitted with vintage bakelite plugs on one end and a custom made junction box at the other.

Instructions (English):

Pfaff Automatic 362-261

Description coming soon

Instructions (English):

Phoenix Class 82 (Baer & Rempel)

Phoenix sewing machines were made at the ‘Nähmaschinenfabrik Baer & Rempel’ in Germany. The Class 82 model was introduced in 1948, at the height of allied disdain for all things German. This might explain why the words ‘Made in Germany’ were painted over on this machine, although this particular machine dates from 1952, according to the printer’s code on the back of the instruction manual. The machine features a ‘positive throw’ zigzag mechanism, meaning that the needle is moved in both directions mechanically, rather than being pushed one way and returned by means of a spring. This produces more accurate stitching and is a hallmark of good quality.

Phoenix Class 282 / 282F (Baer & Rempel)

Another well designed sewing machine from the ‘Phoenix’ range, the model 282 was available in several versions. The flat-bed, supplied with treadle or electric ‘motive power’ or the 282F free arm electric type with its beautiful curved timber extension table. It has been described (by a woman) as a very ‘masculine’ machine, what ever that may mean. It certainly is typically German in its design and features the unique and patented ‘anti-tangle’ bobbin case design. Curiously, the instructions were supplied in two parts. One booklet contains the details on how to operate the machine, the other speaks of the usefulness of the attachments and how they work. Both these publications were printed in November 1957.

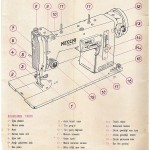

Instructions (English):

Singer 15K

Singer 27-4

Made in August 1903. this is by far the oldest machine in Rudolf’s collection. It is still in perfect working order, although it sews only straight in a forward direction, it is a difficult task cranking the handle and guiding fabric at the same time! Still, 111 years ago, a device such as this would have saved many hours of hand stitching.

Singer 66K

This particular machine dates from 1922 and it came in as a patient for repairs. Dusty and neglected, it soon came back to life. Now polished up, tuned and missing parts replaced, it is in complete working order.

Instructions (English):

Singer 99K

Pictures and description coming soon

Singer 127 / 128K

This machine, which dates from 1923, was on its deathbed when Rudolf came to the rescue. Inhabited by cockroaches and redback spiders, it suffered exposure on a verandah for who knows how many years. Covered in dirt and grime and seized up with rust, it was in a terrible state. Seemingly a lost cause, there lay untold beauty beneath the surface. Its paintwork and transfer decorations still mostly in tact, it just took a bit of gentle cleansing to bring it back to its former glory. With the mechanism partly disassembled, it could be unstuck a bit at a time, until it turned freely once again. Each part was cleaned and polished and put back in its place. The woodwork probably suffered the most damage, with parts of it rotted away to nothing. Still, it was salvageable. The key to this restoration was to make things appear as though they had never been any different!

Instructions (English)

Singer 201K

The Singer 201 K was produced in at least two different versions. The earlier models had the classic rounded shape with filigree cover plates. Later examples looked more angular and were updated to be similar to the 306K and 319K models. In fact, they shared many common parts, including the head cover plate, electrical gear and even carry cases and work tables. Throughout the years, they would have been available as hand-crank, treadle or electric motor driven variants. One might have started with the basic equipment and added a light or an electric motor later on. One interesting thing about the 201K is, that the needle is threaded from right to left, a most unusual arrangement.

Instructions (English)

Singer 306K

The 306 was produced in a variety of versions, with and without ‘Fashion Disc’ capability. All of them can do straight and zigzag stitching and have needle position control., while only the ‘Automatic’ is set up for the fancy stitch patterns. They are very similar to the 206K, 319K and 322K2 and they share many parts with these models.

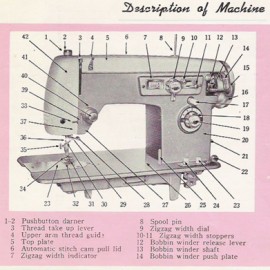

Instructions (English)

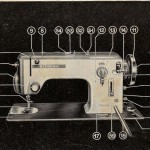

Singer 319K

This machine’s milkshake green colour is giving away its age, having been made in Great Britain in 1958. Featuring five built-in fancy stitch patterns as well as the facility for use of ‘Singer Fashion Discs’, a spring loaded lever connected to the needle bar traces the edges of these discs as they rotate, thus influencing the stitch width. These machines were produced in their tens of thousands and were available in black and gold livery as well. Some of the information in the instruction booklet may be adapted to Singer model 320K2, as these two models are quite similar.

Instructions (English)

Singer 320K2

This model is essentially a free arm version of the 319K. It features a very cleverly designed timber box which clips together to surround the base of the machine and thus transforms it into a flat-bed machine.

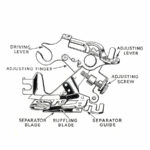

Singer Ruffler Attachment

This model is essentially a free arm version of the 319K. It features a very cleverly designed timber box which clips together to surround the base of the machine and thus transforms it into a flat-bed machine.

Instructions (English)

White VS III

Treadle powered vibrating shuttle machine made in the USA, dating from about 1915. White was the only real competitor to Singer in the early 20th Century, but unlike them, White limited their range to just a few basic models. While not finished quite as well as Singer machines of the period, this item has stood the test of time. As with many early sewing machines, its bobbin thread is carried in a bullet-shaped shuttle, which swings back and forth to form the stitches. It sews straight stitching in a forward direction only. A lever arm operated by means of an eccentric disc ensures the bobbins are wound evenly. The cabinet contains a rather nifty mechanism, which folds parts of it away, as the machine is being lifted. An interesting bit of information is that White owned their own forests and sawmills, which supplied timber to their cabinetmaking workshops.